| This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 817999 |

News & Events

BIOFIT Final Policy Conference, January 2022 - Presentations and Stream available

BIOFIT Project Meeting - Main Results, 19-20 October 2021

BIOFIT peer-reviewed publication on "Public Acceptance", October 2021

BIOFIT Sectoral Recommendation Papers published, August 2021

BIOFIT virtual Business Mission to Ukraine - Webinar 10.11.21 - Presentations available

BIOFIT virtual Business Mission to Ukraine - Webinar 22.09.21 - Presentations available

BIOFIT Industry Forum on Bioenergy Retrofitting of Refineries, 17 June 2021

BIOFIT Report on Public Acceptance published, May 2021

Concawe, BDI and BTG-Bioliquids at 6th BIOFIT Meeting, 24 March 2021

BIOFIT offers virtual Business Mission to Brazil, 24-26 May 2021

BIOFIT Industry Forum on CHP and heat only sector, 19 April 2021

BIOFIT Sponsorship at Fuels of the Future Conference, 18-22.01.2021

BIOFIT Online Seminar on Retrofitting approaches in the field of Lignocellulosic Ethanol, 25.11.2020 – Presentations available

Press Release – Summary for Policymakers published

Press release - 17 September 2020

BIOFIT Sponsorship at European Bioenergy Future Conference, 18-20.11.20

BIOFIT at e-EUBCE 2020

Interview with Dr Edgar Ahn, BioEnergy International (BDI)

New publication in the framework of BIOFIT

BIOFIT Industry Form - H2020 Project on Bioenergy Retrofits for Europe’s Industry, 9 July 2020

Total Refining and Chemicals

BIOFIT Case Study: Co-feeding of pyrolysis oil in a fossil refinery to produce green transport fuels

Together with project partners TFMC and BTG, the co-feeding of pyrolysis oil in the FCC (Fluid Catalytic Cracker) of a Total refinery has been investigated. This way, green, second-generation (advanced) biofuels can be produced. BIOFIT partners BEST and CERTH have worked respectively on the supply chain and the environmental assessment.

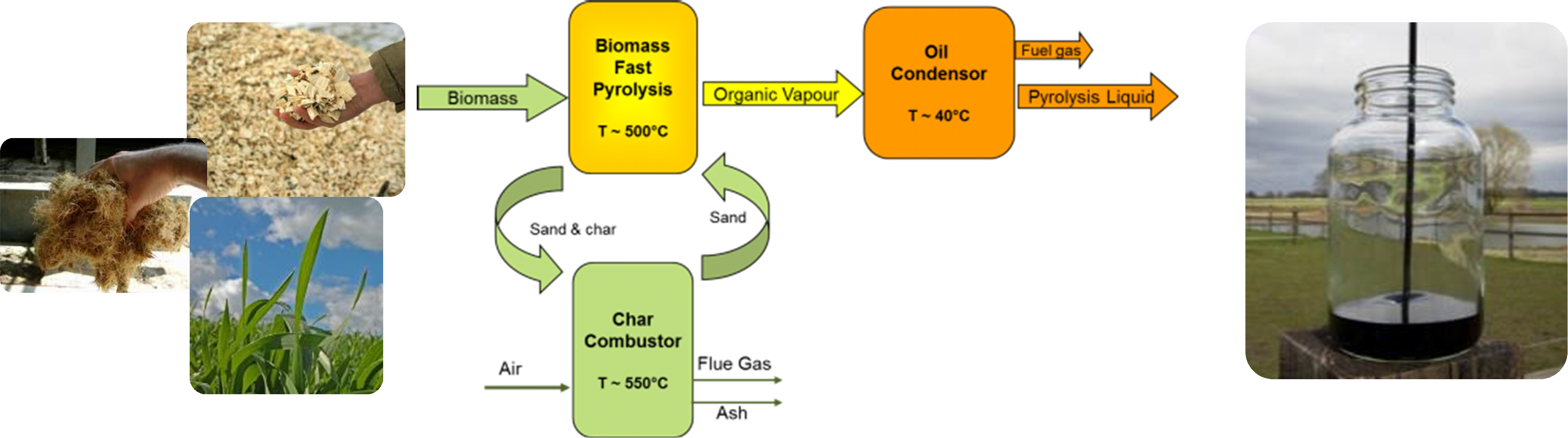

Pyrolysis oil is produced from lignocellulosic materials, such as forestry residues and wood waste. Pyrolysis oil has a high energy density, which means that it can be transported and stored easily at low-cost.

Figure 1: Pyrolysis oil production

Distributed production of pyrolysis oil can take place, followed by transport to a single location, such as a refinery. Advantages of this concept are that only limited new infrastructure needs to be build, namely the pyrolysis oil production plants. These are relatively small, can be constructed fast (in 1 year), and capital requirements are modest in comparison with the costs of a refinery. Retrofitting costs at the refinery are low.

Figure 2: Pyrolysis oil production and co-feeding value chain

The whole value chain is financially viable and the resulting CO2 emission reductions are substantial, and well above the RED II thresholds.